In the world of textiles, a new contender is rising – bamboo fiber. Hailed for its eco-friendly qualities and luxurious comfort, bamboo fiber is quickly gaining popularity among sustainable fashion enthusiasts and conscious consumers. But what exactly makes bamboo fiber so special? Let’s delve into its properties, production process, and its blossoming presence in the textile industry.

Properties of Bamboo Fiber:

Bamboo fiber boasts a unique combination of properties that make it stand out from traditional materials like cotton or polyester. Here are some key features:

Softness and Comfort: Bamboo fiber is incredibly soft and smooth against the skin, making it ideal for clothing and bedding.

Breathability: The natural structure of bamboo allows for excellent air circulation, keeping you cool and comfortable in warm weather.

Moisture Absorption: Bamboo fibers excel at wicking away moisture from the body, keeping you dry and comfortable during physical activity.

Odor Resistance: Bamboo possesses natural antibacterial properties that help suppress the growth of odor-causing bacteria.

Durability: Bamboo fabric is surprisingly strong and durable, making it a long-lasting choice when cared for properly.

Eco-Friendly: Compared to traditional materials, bamboo is a renewable resource that requires less water and land to grow.

The Making of Bamboo Fiber:

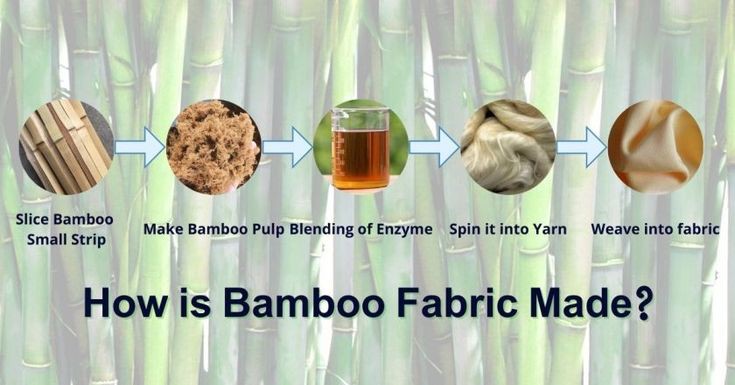

The process of transforming bamboo into a textile involves several steps:

- Harvesting: Mature bamboo culms (stalks) are harvested, typically from sustainably managed forests.

- Crushing and Soaking: The culms are crushed into a pulp and soaked in a solution to remove lignin, the natural binding agent.

- Degumming: The degumming process further purifies the pulp by removing any remaining impurities.

- Dissolving and Spinning: The purified cellulose is dissolved into a liquid and then spun into fine bamboo fibers through various methods.

- Weaving and Knitting: The bamboo fibers are then woven or knitted into fabrics for a variety of textile applications.

Where Does it Come From?

While bamboo grows in many parts of the world, the majority of bamboo fiber production currently takes place in China. However, as the demand for sustainable textiles increases, other countries like India and Vietnam are also ramping up their bamboo fiber production capabilities.

Bamboo Textiles:

Bamboo fiber is finding its way into a diverse range of textile applications, including:

Clothing: From soft t-shirts and comfortable loungewear to luxurious pajamas and activewear, bamboo offers a sustainable and comfortable alternative.

Bedding: Bamboo sheets are known for their exceptional breathability and moisture-wicking properties, creating a cool and comfortable sleep environment.

Towels: Bamboo towels are highly absorbent and dry quickly, making them a hygienic and eco-friendly choice.

Home Textiles: Bamboo fibers are also used in various home textiles like rugs, curtains, and tablecloths.

As the demand for sustainable and ethical fashion grows, bamboo fiber is poised to play a significant role in the future of textiles. With its impressive properties and eco-friendly credentials, bamboo fiber offers a compelling alternative to traditional materials, paving the way for a greener and more sustainable future for the fashion industry.