Introduction

Technical textiles have a significant impact on vehicle performance and comfort in the automotive sector. These specialty textiles provide benefits including lightweight design, high strength, and increased durability and are made to fulfill particular functional requirements.

History

Since the early days of the motor vehicle, textiles have been used in automotive construction. Traditionally, furniture and carpets were made of natural fibers like cotton and wool. But the 20th century saw the invention of synthetic fibers, which was a huge turning point. Superior performance features of materials including nylon, polyester, and aramid fibers led to their greater acceptance in a variety of automotive applications.

Types and Applications

Today, a diverse range of technical textiles are used in various parts of an automobile. Some key examples include:

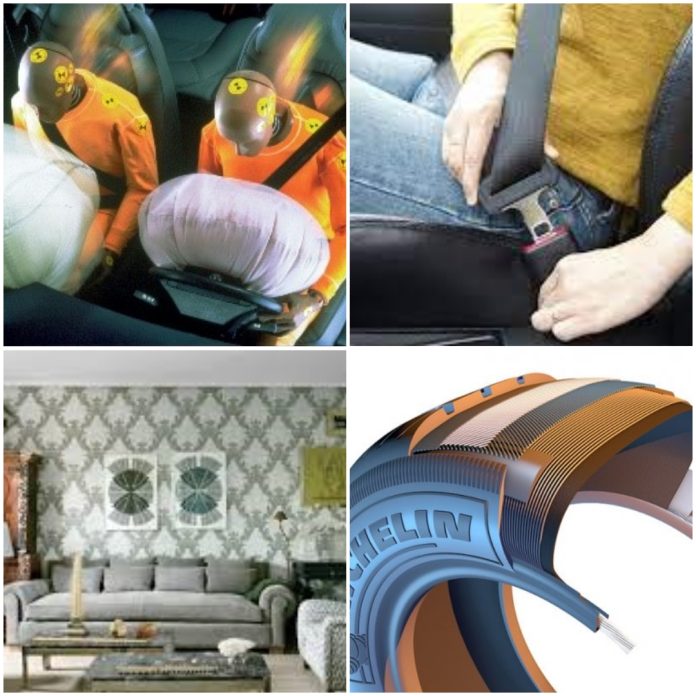

Tire cord materials: The structure of tires is strengthened by these high-strength, low-stretch materials, guaranteeing their performance and longevity.

Airbag fabrics: Airbag fabrics: Made of high-tenacity fibers, these textiles must quickly unfold and be able to withstand inflation force in the event of a collision in order to protect passengers.

Seat belts: In order to secure people in the event of an accident, these knitted or woven materials must have a high strength to low elasticity ratio.

Interior fabrics: Interior textiles: Technical textiles provide comfort, sound absorption, and visual appeal and are used for upholstery, headliners, door panels, and other interior components.

Filters: To capture impurities and guarantee the engine operates at its best, technical fabrics are utilized in fuel, oil, and air filters.

Benefits

In the automobile sector, technical textiles have the following benefits:

Lightweight construction: Technical textiles can result in lower emissions and fuel economy because they are frequently lighter than conventional materials like steel or aluminum.

High strength and durability: By withstanding heavy loads and strain, these materials maintain the functionality and safety of automobiles.

Increased comfort: By providing vibration damping, sound absorption, and thermal insulation, technical textiles can improve passenger comfort.

Design flexibility: Technical textiles can be developed to fulfill particular design specifications, giving designers of vehicles more freedom.

Cost-effectiveness: Technical textiles frequently provide higher performance at a lower cost than traditional fabrics.

Disadvantages

Using technology fabrics in cars has many drawbacks in addition to its benefits. These include:

1. Higher initial cost: Compared to traditional materials, technical textiles may be more expensive initially, but this may be justified by the long-term performance advantages.

2. Limited availability: A supply chain may encounter difficulties if certain specialist technical textiles are not easily accessible.

3. Recycling and disposal: Compared to traditional materials, properly recycling and disposing of technical textiles at the end of their useful lives can be more difficult.

Summary

In the car sector, technical textiles are becoming more and more significant since they enhance comfort, safety, performance, and fuel efficiency. We anticipate seeing even more cutting-edge uses for these adaptable materials in the future as technology develops.

- Information Sources:

- Textiles Intelligence: https://www.textilesintelligence.com/

- Fibre2Fashion: https://www.fibre2fashion.com/industry-article/1807/application-oftextiles-in-automobile

- Technical Textile Association: https://www.ittaindia.org/

- International Association of Nonwoven Fabrics: https://www.nonwovensindustry.com/buyersguide/profile/inda-association-of-the-nonwoven-fabrics-indu/

Writer’s Information:

Md Imranul Isalm

Department of Textile Engineering

Green University of Bangladesh (GUB)

Email: [email protected]