- Material Selection:

Bangladesh has a high production rate of bamboo which has very vast use in various sections and one of that is bamboo fiber. Bamboo fabrics have many useful features that can create a healthy atmosphere at one’s home. Bamboo fiber is the new natural and eco-friendly textile material of the 21st century. Bamboo fabric is gaining popularity due to its exceptional properties, and is 100% biodegradable. It is said that “Bamboo fiber comes from nature, and returns to nature in the end”.

- Production of Bamboo Fiber:

Bamboo fiber is a regenerated cellulosic fiber produced from bamboo. Starchy pulp is produced from bamboo stems and leaves through a process of alkaline hydrolysis and multi-phase bleaching. Further chemical processes produce bamboo fiber. These fibers are cleaned, bleached and dried in the final step. This is how long, white and strong fibers are made from the bamboo pulp.

- Footprint of Secondary Resources:

Bamboo fiber has a very low impact on secondary resources. Bamboo proliferates and doesn’t require the use of pesticides or fertilizers. It also doesn’t need much water to grow. Bamboo only needs about one-third the amount of water that’s required to grow trees which means bamboo needs the less amount of water, energy and chemicals. Bamboo needs a very low amount of soil to grow. 3 feet by 3 feet for the Clumpers and 3 feet by 10 feet for the Runners and the hole should be deep enough so the root ball can sit slightly lower than it was in the container, with 2–3cm (1in) of soil covering the original surface. Fill in around the root ball with a mix of soil and garden compost, then firm in. Bamboo is easier to harvest and the least labor intensive.

- Turning Textiles from Bamboo:

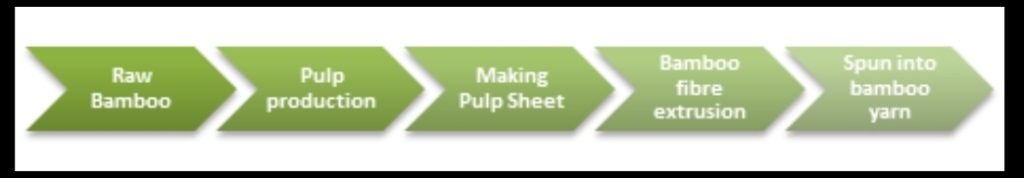

Several essential stages undergo to covert bamboo into textiles:

- Regeneration of Cellulosic Fiber:

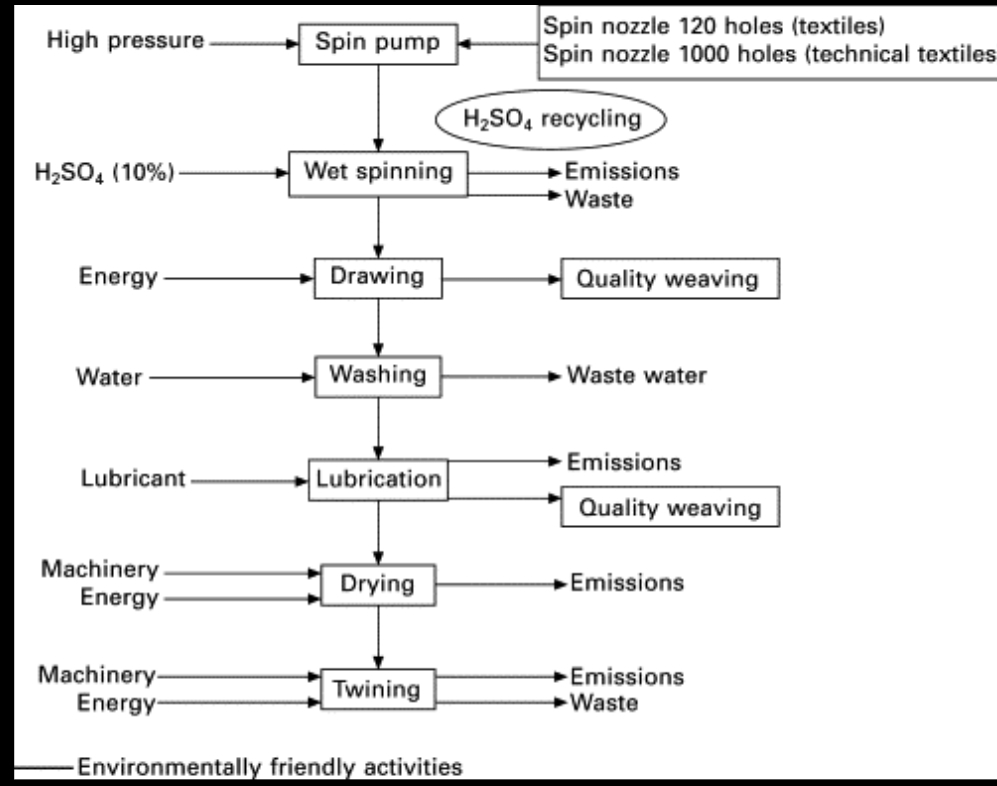

Regenerated cellulose is a class of materials manufactured by the conversion of natural cellulose to a soluble cellulosic derivative and subsequent regeneration, typically forming a fiber. An Overview will be:

- Process of Alkaline Hydrolysis:

Alkaline hydrolysis allows the partial separation of the cellulose fibers from the cell wall. These treatments are usually made using diluted solutions of NaOH (1–10%) at low or high temperatures and of concentrated NaOH solutions at low temperatures. NH4OH and anhydrous NH3 (gas or liquid) are also used to activate the organic materials. It is an is an alternative to burial or cremation.

- Multi-Stage Bleaching:

Multistage bleaching of kraft pulps has two primary phases: lignin-removal and enhancing whiteness. In the first stage of the bleaching process, the pulp is exposed to chlorine gas, which allows the lignin and its related impurities to dissolve easily in a caustic water solution.

- Bamboo Fiber extraction through Rayon process:

The bamboo culm is crushed into smaller fractions and soaked in a solution of 18 % NaOH at 20–25 °C for 1–3 h to form alkali cellulose. 2. The bamboo alkali cellulose is pressed to remove excess NaOH solution, crushed by a grinder and left to dry for 24 h. Then the fiber is extracted from the crushed grinder. The process follows:

- Consumers of Bamboo Fibers:

Asia Pacific is anticipated to be a leading region in the global market of bamboo fiber. The increasing cultivation of bamboo create new opportunities for market players. Moreover, bamboo is one of the fastest growing plants. The main consumers of bamboo fibers are local markets, some eco-friendly fashion brands and environmentally conscious customers. The prominent players in the global bamboo fiber market include Bamboo Textile Co., Shanghai Tenbro Bamboo Textile, Advantage Fibers, Wild Fibers etc.

- End-of-Life Strategy for Bamboo Fiber:

Bamboo can be made into reusable and disposable. The strategy will be:

- Waste Collection and Redistribution:

It is possible to recycle and dispose bamboo fiber waste. Crusher machines are used to first turn plastic to powder, and then the same process is used to turn discarded and useless bamboo parts, collected from waste, and turn into powder. The powder made out of waste and discarded plastic and bamboo is then mixed in requisite proportions and turned into a composite pulp. The pulp is then molded with the help of a machine to take the shape of plates and bowls.

- Recyclability and Biodegradability:

If your bamboo products are 100% natural, such as Jungle Straws or Jungle Culture’s bamboo cutlery then composting is almost certainly the most environmentally friendly way to recycle bamboo. Due to bamboo fibers anti-bacterial property, the bamboo fibers have wide prospects in the field of hygiene home textile items and it can be bio-degradable.

At the end, bamboo fibers are commonly used fiber materials that can make an eco-friendly environment with a very cost sufficient manner.

Written by-

Nopur Akter

Ahsanullah University of Science & Technology,

4th year, 1st Semester