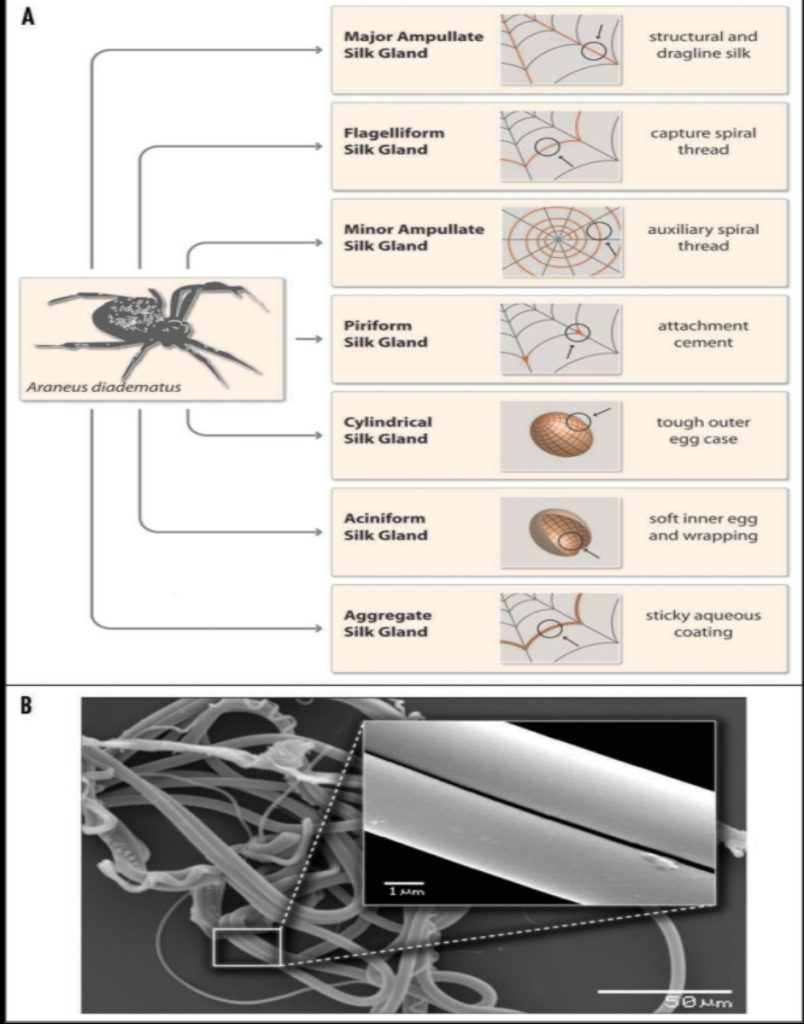

Spider silk is a protein fibre or silk spun by spiders. Spiders use silk to make webs or other structures that function as adhesive traps to catch prey, to entangle and restrain prey before biting, to transmit tactile information, or as nests or cocoons to protect their offspring. They can also use the silk to suspend themselves from height, to float through the air, or to glide away from predators. Most spiders vary the thickness and adhesiveness of their silk for different uses.

Abstract

Biomaterials, having evolved over millions of years, often exceed man-made materials in their properties. Spider silk is one outstanding fibrous biomaterial which consists almost entirely of large proteins. Silk fibers have tensile strengths comparable to steel and some silks are nearly as elastic as rubber on a weight to weight basis. In combining these two properties, silks reveal a toughness that is two to three times that of synthetic fibers like Nylon or Kevlar. Spider silk is also antimicrobial, hypoallergenic and completely biodegradable.

This article focuses on the structure-function relationship of the characterized highly repetitive spider silk spidroins and their conformational conversion from solution into fibers. Such knowedge is of crucial importance to understanding the intrinsic properties of spider silk and to get insight into the sophisticated assembly processes of silk proteins. This review further outlines recent progress in recombinant production of spider silk proteins and their assembly into distinct polymer materials as a basis for novel products.

Strength is measured based on several properties. Spider silk is as strong as steel or in some cases even stronger when it comes to tensile strength, which measures the amount of stress a material is able to withstand before breaking, Phys.org(Opens in a new window) reports. Tensile strength is measured in force per unit area, or GPa. The tensile strength of steel ranges from 0.2 GPa to 2 GPa, while the tensile strength of some

spider silks is about 1 GPa.

Is Spider silk as strong as steel?

Because spider silk is so much smaller than steel, it’s hard to fully understand the comparison in terms of strength. Airplanes and skyscrapers — objects designed to withstand many different elements and forces — are made of steel and other strong metals, so it can be hard to think of something as inconsequential as spider silk as being stronger. In terms of strength-to-density ratio, however, spider silk is far stronger than steel, according to Treehugger(Opens in a new window). Essentially, that means a strand of silk is much stronger for its size than a steel beam is.

But tensile strength and strength-to-density ratio are not the only properties of strength, and when it comes to others, spider silk is no match for steel. For example, stiffness is another important property of strength, measuring a material’s ability to change shape elastically when force is applied. In this case, spider silk is nowhere near as stiff as steel, according to Phys.org.

Still, though, it’s fair to say spider silk is stronger than steel, at least in some capacities. The tensile strength of steel comes from its design. A strand of spider silk is made up of many smaller strands — thousands to be exact, Science magazine(Opens in a new window) reports. This is even more impressive when you consider that a strand of spider silk is 1,000 times thinner than a strand of human hair. That means those thousands of smaller strands, called nanostrands, must be infinitesimally small — each only 20 millionths of a millimeter in diameter.

How spider webs achieve their strength

It’s not just the strength of the silk itself, a new study finds; the silk’s way of stretching and the structure of the whole web help it resist damage.

The silk that spiders use to build their webs, trap their prey and dangle from your ceiling is one of the strongest materials known. But it turns out it’s not simply the material’s exceptional strength that makes spider webs so resilient; it’s the material’s unusual combination of strength and stretchiness — silk’s characteristic way of first softening and then stiffening when pulled. These properties, scientists have found, vary depending on the forces applied, as well as on the overall design of the web.

Spider Silk: Wonder Material Used to Heal the Human Body

By: Robin Fearon

Spider silk is one of nature’s wonder materials, more flexible than nylon, thinner than a human hair, and, for its weight, stronger than steel. Webs and nests are spun from this incredible natural protein and spiders use thin threads to glide through the air and escape from predators. Now science is looking to exploit silk’s properties as a way to deliver medicines and heal our bodies.

July 29, 2020

The medicinal benefits of raw spider silk have been known for centuries. Ancient Greeks and Romans cleaned wounds with honey and vinegar and then used balled-up spider webs to stop the bleeding.

Human uses

A cape made from Madagascar golden orb spider silk

The earliest recorded attempt to weave fabric from spider silk was conducted in 1709 by François Xavier Bon who, using a process similar to creating silkworm silk,

wove silk derived spider’s egg cocoons into three pairs of stockings and gloves. Fifty years later the Spanish Jesuit missionary Ramón M. Termeyer , invented a reeling device for harvesting spider’s silk directly from a spider’s body, allowing it to be spun into threads. Neither Bon nor Termeyer were successful in producing spider’s silk in commercially viable quantities.

The development of methods to mass-produce spider silk has led to the manufacturing of military, medical, and consumer goods, such as ballistics armour, athletic footwear, personal care products, breast implant and catheter coatings, mechanical insulin pumps, fashion clothing, and outerwear. However, due to the difficulties in extracting and processing substantial amounts of spider silk, the largest known piece of cloth made of spider silk is an 11-by-4-foot (3.4 by 1.2 m) textile with a golden tint made in Madagascar in 2009. Eighty-two people worked for four years to collect over one million golden orb spiders and extract silk from them. In 2012, spider silk fibres were used to create a set of violin strings.

Medical applications

Peasants in the southern Carpathian Mountains used to cut up tubes built by Atypus and cover wounds with the inner lining. It reportedly facilitated healing, and even connected with the skin. This is believed to be due to the antiseptic properties of spider silk and because the silk is rich in vitamin K, which can be effective in clotting blood. The silk of Nephila clavipes was used in research concerning mammalian neuronal regeneration.

Scientific instruments

Spider silk has been used as a thread for crosshairs in optical instruments such as telescopes, microscopes, and telescopic rifle sights. In 2011, spider silk fibres were used in the field of optics to generate very fine diffraction patterns over N-slit interferometric signals used in optical communications. Spider silk has been used to create biolenses that could be used in conjunction with lasers to create high-resolution images of the inside of the human body.

Refference :

1. https://en.wikipedia.org/wiki/Spider_silk

2.https://www.ncbi.nlm.nih.gov/pmc/articles/PMC2658765/

4. https://www.discovery.com/science/spider-silk–wonder-material-used-to-heal-the-human-body

Submitted by:

Mahbub Rahman

Ahsanullah University of Science & Technology,

3rd Year 1st Semister